Provides precise 5-axis machining with the same operation as 3-axis

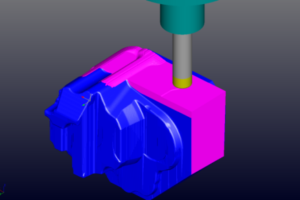

Multiple job setups would be required when machining can’t be finished from one direction. These multiple setups prevent the efficient and accurate cutting of the mold or component, because the work piece has to be manually re-positioned, re-indicated, and picked up again before machining can continue.

3+2 axis machining with CAM-TOOL eliminates the extra setups by machining from different directions, and improves both efficiency and the accuracy.

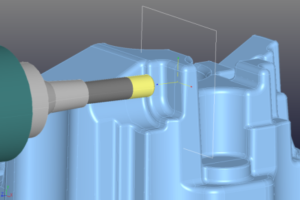

Determination of Machining Direction

Provides a variety of commands such as “Undercut Check”, “Extract FlatPart”, and “Angle Shading” for determining the machining direction needed for 3+2 axis machining. Specifying work plane for determining machining direction, plus saving and returning to the work plane setting can be done with a simple operation.

Optimization from Multiple Directions

Optimization for 3+2 axis machining can be performed effectively after CAM calculation. Optimizations such as “Simulation” that includes displaying undercut areas and “Delete air-cut” by machining from multiple directions, make it possible to provide efficient and highly reliable machining data.