Assistive functions for productivity and safety

Unparalleled tool path reliability saves labor and allows for safe unattended machining

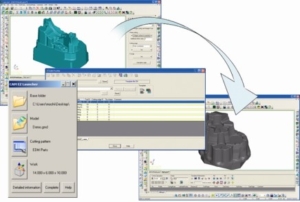

Template / CAM EZ Launcher

Template, the function to register machining-pattern, and CAM EZ Launcher, simplify the CAM operation significantly, allowing for the standardization and reduction of CAM processes.

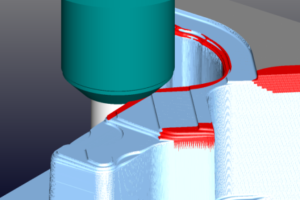

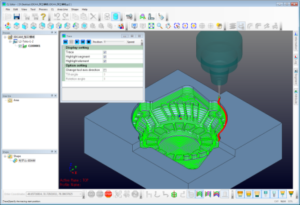

Check Overcut / Remains

Compare the results between the simulated solid of the selected process and the product shape solid.

CL Editor

With a User Friendly GUI, it’s possible to edit and check various types of CL.

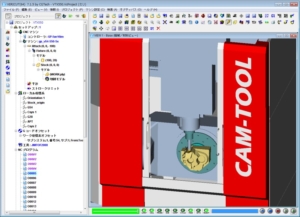

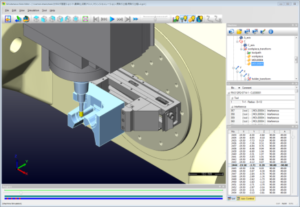

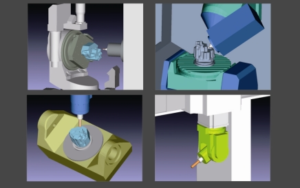

Machine Simulation (Option)

Allows for the detection of CL interference against the component parts of the machine-tool, and verifies stroke-range for each axis. Utilizing the same GUI as “Simultaneous 5-axis Editor”, it provides a user-friendly environment for easy operation.

Peripheral solutions for automation and labor efficiency

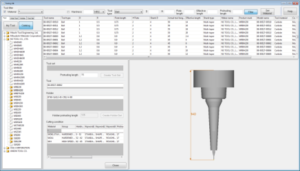

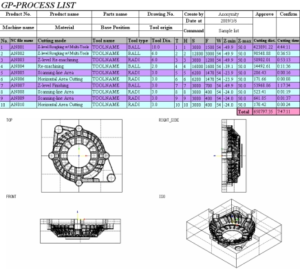

Process sheet

Process sheet or tool list can be output when NC data is created.

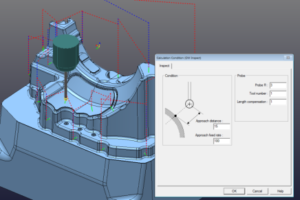

OM Inspect (Option)

This is the command for inspecting the machining precision directly on a machine. Accurate inspection is possible by using the same system for both creating machining data and setting points to inspect. Efficient inspection is possible, and outputting an inspection result into a file is also available.

Post Processor

Use the NC Machine Parameter File format to drive the CNC controller. NC data can be output with simple settings.

5-axis positioning compliant: Tool Center Positioning Control / Tilted working plane command.

VERICUT I/F (Option)

The Vericut interface provides seamless operability from CAM-TOOL to Vericut. Export the tooling data (tool and holder), NC program name, and tool number into Vercicut automatically. For simultaneous 5-axis machining, it allows for both safe and effective machining by checking machine tool interference.